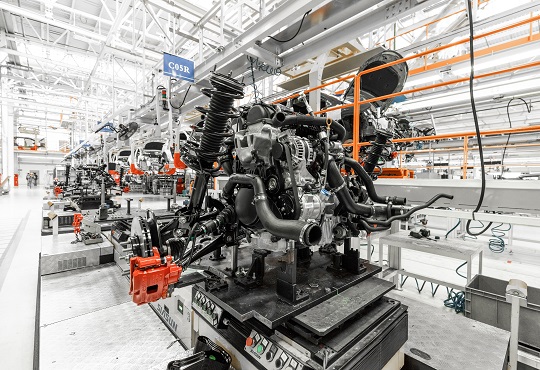

India's Auto industry to Fund $7 bn in 5 years To Deepen Parts Localisation

CIOTechOutlook Team | Friday, 01 March 2024, 04:26 IST

Indian auto industry is set to contribute up to $7 billion, or about Rs 58,000 crore, by FY28 to develop localization of cutting edge parts from electric motors to programmed transmissions to lessen imports and profit by multinationals' 'China In addition to One' obtaining methodology.

Indian auto industry is set to contribute up to $7 billion, or about Rs 58,000 crore, by FY28 to develop localization of cutting edge parts from electric motors to programmed transmissions to lessen imports and profit by multinationals' 'China In addition to One' obtaining methodology.

Automakers and their providers are probably going to make this venture somewhere in the range of FY24 and FY28, industry body Auto Part Producers Affiliation (ACMA) said.

These organizations have previously embraced more than 500 localisation projects across 11 key part classes, including drive transmissions and controlling, motors, electricals and body frame at a speculation of over Rs 3,000 crore to decrease net imports by 5.8% (twofold the objective of around 3%), or by Rs 7,018 crore, in the two years to FY22, according to the most recent evaluation on localization programs mutually directed by ACMA and Society of Indian Automobile Manufacturers (SIAM).

Work is on to increment net localization by another 16-20%, or about Rs 24,995 crore, over the accompanying five years finishing FY27, they said. Projects are in progress to lessen imports of airbags to 20% by 2028 from 26% in 2023 and 100 percent in 2012, those of electronic strength control units to 47% by 2025 from 63% in 2023 and 100 percent in 2015, and imports of ventilator fan frameworks to 10% by 2026 from 85% in 2024 and 100 percent in 2021.

Plans to develop localization of programmed transmissions, power control units, high-strength steel, and consolidated charging frameworks are additionally on the cards mid-term. These parts represent over 75% of vehicle parts brought into the country. Other than lessening imports, the business additionally hopes to make India a commodity center for cutting-edge auto parts.

“World over, the industry is building resilient supply chains by reducing overdependence on any particular country or geography,” said Shradha Suri Marwah, president of ACMA.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)